Become Eco-Effective

Pioneering performance and eco-effectiveness: Pioneer Series is our most revolutionary and complete range of solutions. Every aspect of them is refined to create the ultimate finish while ensuring sustainability. It’s why all Pioneer Series products are eSense products, manufactured based on renewable resources. Highly economical, productive and efficient, Pioneer Series is guaranteed to deliver exceptional results.

#EcoEffectiveness by R-M

Everyone wins with #EcoEffectiveness by R-M

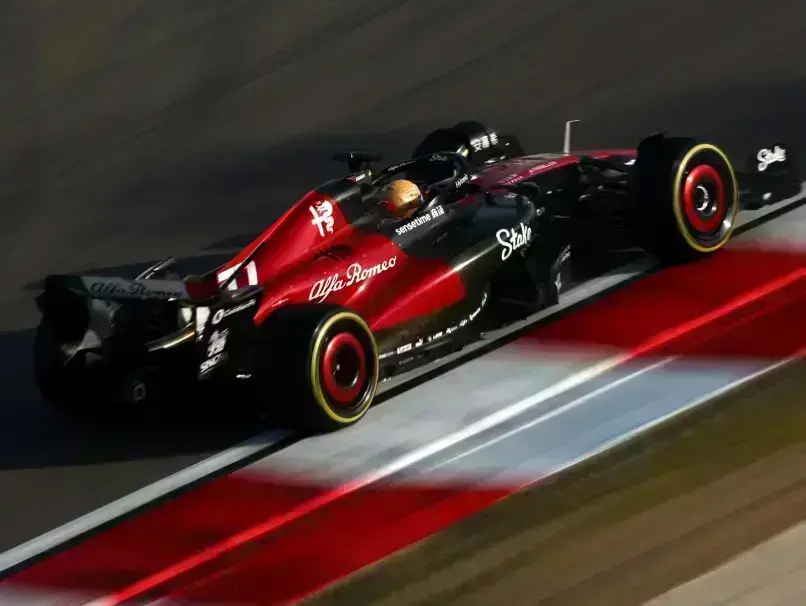

R-M is much more than a premium paint manufacturer. It operates as a global brand, a genuine business partner with a profiled team of consultants, technical experts and service teams and has been recognized as a major player in automotive refinishing for a century. R-M's unparalleled experience, flexibility and customer focus ensures the brand continues to provide the highest level of support and partnership with its innovative, easy-to-use solutions and high color competence - Ensuring increased productivity for our customer’s business success, worldwide.

Team up with R-M and accelerate your business success

Connect with your local R-M dealer now