Product Techs

At R-M Paint, we understand the challenges you face when it comes to refinishing vehicles. That's why we offer a comprehensive range of paint systems and innovative solutions to help you save time and money. From Eco-Effective Solutions to cutting-edge UV technologies, and even ADAS Solutions, we've got you covered.

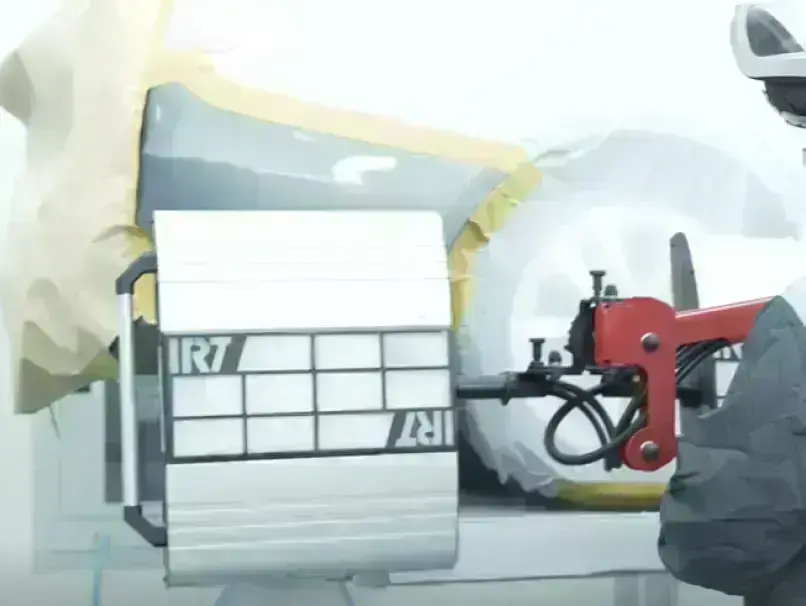

UV technologies

UV-A repairs from R-M at the speed of light

+25%

Up to 25% faster process times when compared to oven and infrared drying

Increase your productivity with the UV-A Portfolio. Save time and effort while delivering outstanding results.

+40%

This faster process leads to 40% more jobs

R-M‘s smart UV-A technology ensures quicker curing times than any other curing method used in bodyshops today. Plus, there’s no need to mix hardeners into the products.

-50%

On average, body shops use up to 50% less energy on each job with UV-A technology

UV-A light offers a huge reduction in VOCs and CO2 emissions in the curing process – making it safer and easier for bodyshops to use and far better for the environment.

eSense

eSense: good for cars and for the environment

The new type of repair – with R-M’s eSense products

Discover products that conserve the environment by reducing CO2 in the manufacturing process, yet still guarantee perfect paint repairs. With R-M’s eSense products, fossil resources are conserved and replaced mathematically by renewable resources. And best of all, the more eSense products our partners use, the higher the share of renewable components is in the future.

Team up with R-M and accelerate your business success

Connect with your local R-M dealer now